A Modern Russian Greenhouse Facility

“Oh, how many wonderful discoveries the spirit of enlightenment can give!”

A. S. Pushkin, a Russian poet.

1.

2. It is sterile clean here. We were asked to put on a uniform so as to protect plants.

3. The first impression of the place is that we got into a futuristic factory! It is 6 meters (19,6 feet) high. There are a lot of sensors, control panels and 700 kilometers (435 miles) of heating tubes. The modern greenhouse facility is automized, so the number of workers in it is very low. We will talk about the personnel and control systems a little later.

4. Let's have a look at the automatic sowing line. It is the beginning of the process of growing.

5. The machine is 12-15 times faster than a gang of 4 workers. At the picture you can see how it sucks up the seeds. After that the seeds are automatically planted into the planting pots, which are also prepared by the machine.

6. You can see the result of the line's work. Each pot, filled with a coconut substrate, has three seeds in it. A seed coating is a process of covering seeds with a protective coat, and it is a part of a presowing treatment.

7. The next step. Trays with "fertilized" pots are placed in a cell with suitable temperature and humidity for greensprouting.

8. After that trays are transported to the seeding room, which is illuminated 24x7. They will sit here for ten days.

9. Tables with plastic trays and a specific solution feed system. The solution washes the plant's roots for fifteen minutes, and then gets back into the system.

10. All those tables are easy to move, and it helps to save the extremely expensive space in the room.

11. Guess, what are those yellow leaves used for? From time to time insects may fly into this hermetic facility, and those yellow things help to kill them. A solution circulates in those white rectangle channels and washes the plant's roots. After twenty days all mature produce will be packed and transported to stores. The facility produces up to four thousand pieces of salad a day.

12. Pay your attention to the number of lamps at the ceiling. The facility must be properly lightened all over the day.

13. An expensive energy has always been a serious problem for modern companies. The facility has no gas, and for that reason the company had to build its own powerful energy substation. It will be launched soon.

14. Here the solution with a given level of EC and pH is prepared of water, mother solution and citric. The computer is controlling the process to prevent mistakes.

15. A user-friendly interface of the watering system is easy to learn and use.

16. It seems to me that we have spent a lot of time in this room. Let's move forward to the section with tomatoes. It's area is two hectares. The real tomato jungles, which are higher than a human! The section with cucumbers is equal to the tomatoes'.

17. The area is equipped with a system of drip watering. It means that every of 350,000 plants has its own dropper. You can see those small tubes at the roots.

18. Talking about women. Men do not do well at this job, even though it seems to be an easy one. Moreover, it is very difficult to find a qualified staff, despite the fact that they are paid well.

19. In a greenhouse facility tomatoes grow up to 14 meters high (46 feet), and women put them on specific bandings. Thin plastic tubes with small holes are everywhere. Those tubes bring carbon dioxide to the plants. Its concentration is absolutely safe for people.

20. Since those cucumbers are pollinated by bees, there is a beekeeping at the facility. Bees are transported from Uzbekistan because they wake up earlier then Russian bees. Thus, they began pollinating earlier, in January or February.

21. Sergey and Nikita are waiting to make a picture of bumblebee, and Nikita even knocks at their cardboard house. I prefer to stay away from them.

22. The picture of ripening tomatoes. Let's move to cucumbers.

23. Tomatoes are planted once a year, cucumbers – twice: November through June and July – November.

24. As you can see, those cucumbers have pimples. My mom and wife buy the same.

25. There is a biological laboratory, which produces mites. Those are used to fight pests and are not dangerous for people.

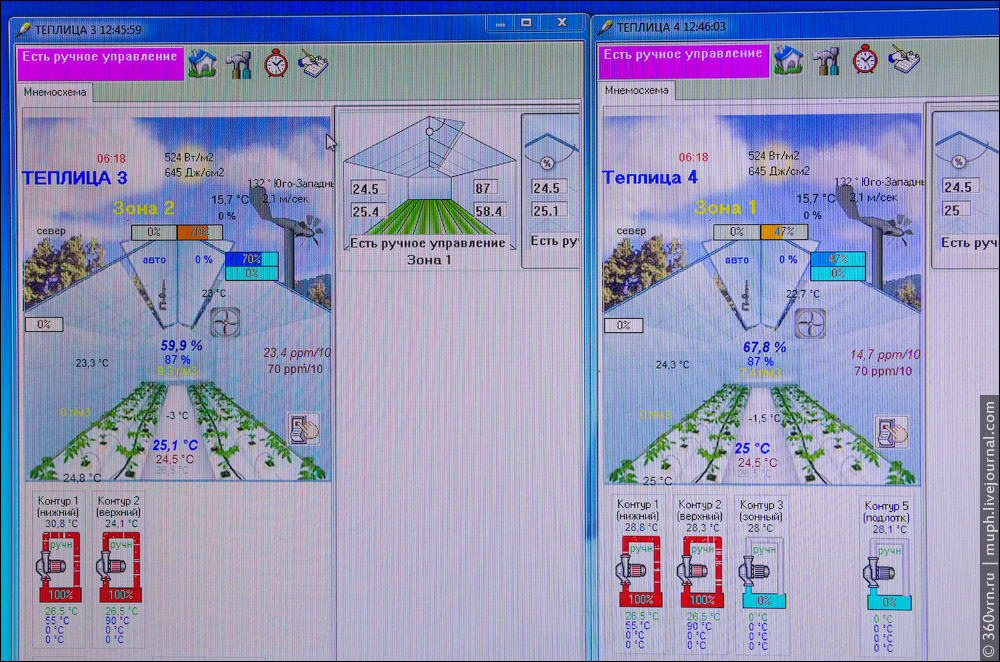

26. And finally a picture of a screenshot with interface of the control program Monitor. It allocates information and provides monitoring of all processes at the facility. The program helps to analyze allocated information and inform its user about problems.